Today, we are capable to provide one-stop metal stamping solutions. We are not only providing Metal Stamping and tool and die design. To fulfill all customer needs across various industry, we invest and enhance our inhouse processes. We collaborate with our business partner to provide various secondary processes for our clients.

- Metal Stamping

- Tool and Die Fabrication

- NC Bender

- Projection Spot Welding

- Tapping

- Argan Welding

- Mechanical Assembly PEM nut

- Riveting Assembly

- Laser Marking

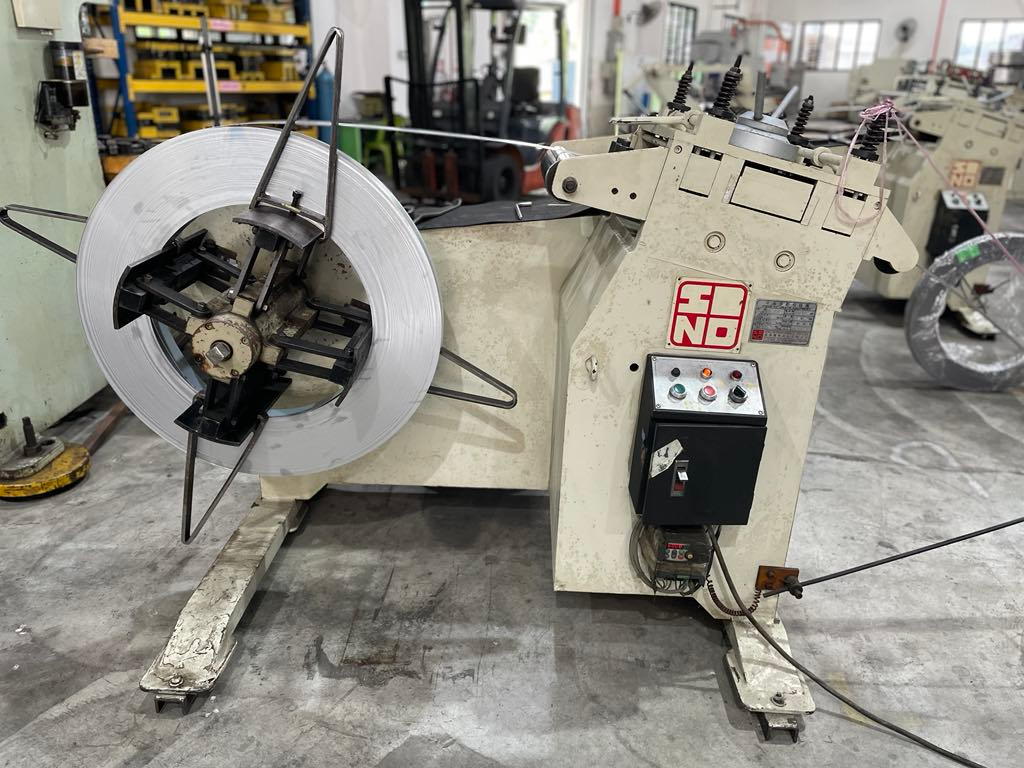

Metal Stamping

a. 26 stamping press machines ranging from 40 to 300 tons.

b. Manufacture ferrous and non-ferrous components with material thicknesses between 0.1 mm and 8.0 mm:

i. Stainless Steel

ii. Cold & Hot -rolled steel

iii. Low-alloy steel

iv. Silver Nickel

v. Pure Nickel

vi. Aluminum Alloy

vii. Copper Alloy

viii. Beryllium Copper

ix. Brass

c. We serve: Sensor Intelligence, Power Tools, Aerospace and Aviation, Military and Safety, Automotive, OEM, Electronics, Home appliances, Conveyor and Racking Industry

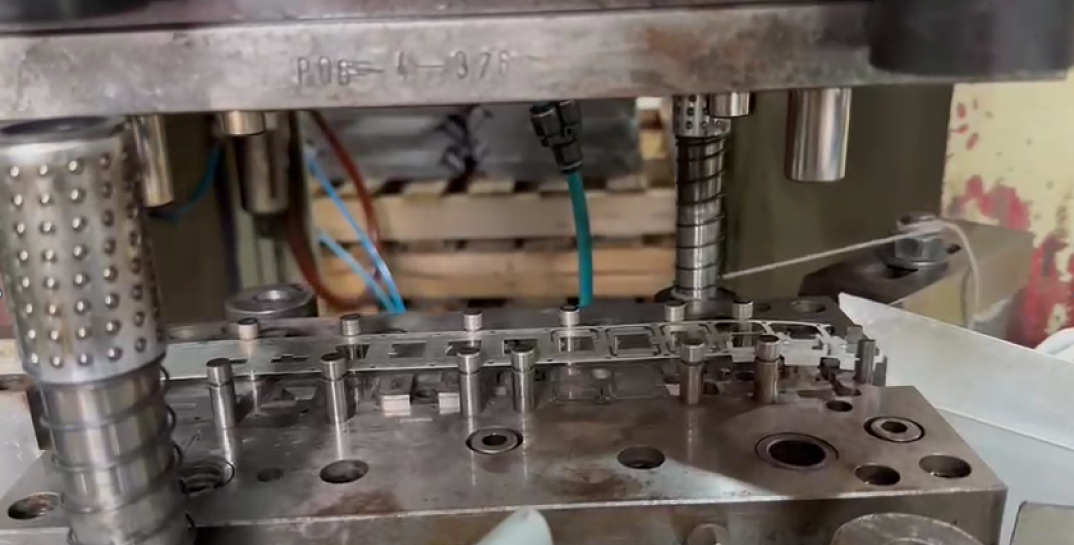

Tool and Die Fabrication

a. Specializing in design and fabrication of a full range of reliable precision dies for both manual and progressive stamping processes.

b. Equipped In-house tool room to offers onsite troubleshooting during mass production and engineering support for our clients.

c. Type of Tooling:

i. Progressive

ii. Compound

iii. Blanking

iv. Piercing

v. Step compression

vi. Deep draw

vii. Forming

viii. Embossing

ix. Bending

x. Coining

xi. Lettering

xii. Chamfering

xiii. Countersinks

NC Bender

The NC Bender is a programmable machine designed to perform a variety of metal sheet bending operations, including forming rounded corners and bending at different angles. It can handle components up to 4 meters in length.

Projection Spot Welding

A form of resistance welding which joins the metal components by using pressure and heat generated by electric current. This offers a more efficient welding with less energy and greater weld strength. Special jig will be designed and fabricated as per the shape of the welding area.

Tapping

Tapping is the process that creates a thread hole. There is various size of taps are available. Special jig will be designed and fabricated according to the tapping holes position to ensure the tapping accuracy.

Argan Welding

TIG and MIG welding

Mechanical Assembly PEM nut

Mechanical assemble metal component with PEM nut using Caulking hard tool.

Riveting Assembly

Assemble metal component with pin, rivet with customized soft tool.

Laser Marking